Dangerous Goods Storage

Dangerous Goods Storage is a crucial aspect of compliance and safety for any organisation that handles hazardous materials. It includes measures such as segregation, labelling, and fire protection to minimise the risk of accidents and spills. This may include the use of specialised storage containers, such as safety cans, and the implementation of strict protocols for handling and transporting dangerous goods.

Chemical Warehousing is an integral part of Dangerous Goods Storage as it provides a safe and secure environment for the storage of hazardous materials. It is essential for compliance with regulations and industry standards, and for maintaining the safety of employees and the general public. Chemical Warehousing facilities must comply with the relevant regulations and guidelines for the safe storage of dangerous goods, must have the appropriate fire protection systems in place, and must be equipped with emergency response plans and procedures in case of an incident. Additionally, chemical warehousing facilities must keep Material Safety Data Sheets (MSDS's) for all dangerous goods stored on-site.

Flammable Liquid Storage Cabinet Bundle

What class of dangerous goods?

Recommended Dangerous Goods Accessories

-

Sale

A37991

Slimline Flammable Liquid Storage Cabinet - 110L

$3,373.11

$2,239.60 -

Sale

A38652

Outdoor Flammable Liquid Storage Cabinet 160L

$5,066.48

$3,301.10 -

Sale

A6219

Flammable Liquid Storage Cabinet 60L

$2,820.40

$1,871.10 -

Sale

A47812

Flammable Liquid Storage Cabinet Value 30L Yellow

$1,275.00

$795.30 -

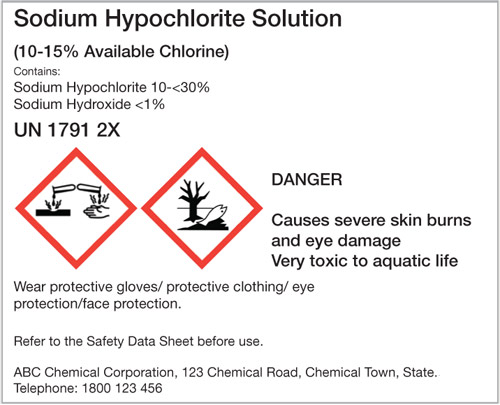

A39473

GHS Custom Labels

-

Sale

A6882

Corrosive Storage Cabinet Steel - 60L, Blue

$2,829.88

$1,861.20 -

Sale

A24960

Aluminium Cylinder Lockers, 4 Cylinder Storage

$2,644.10

$1,889.80 -

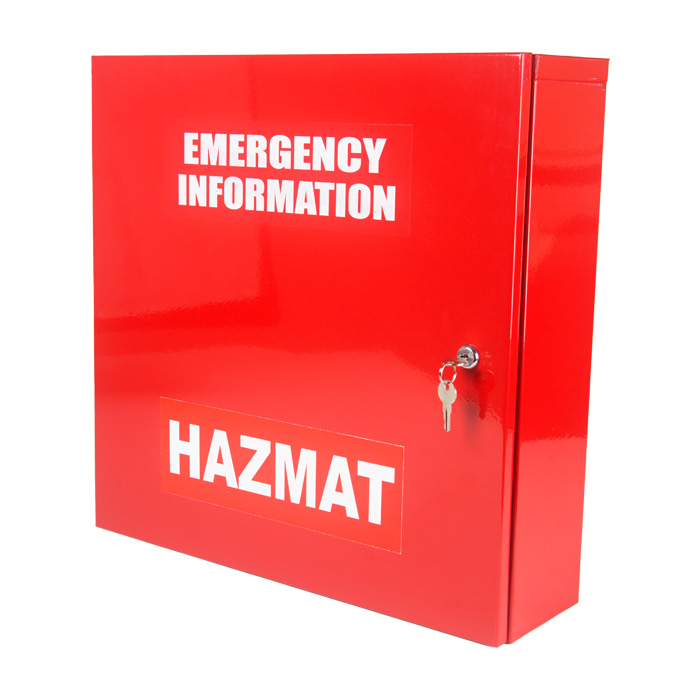

A46881

Value Manifest Cabinet, Large

$457.44 -

A43554

Paint Spray Can Aerosol Storage Cage 72 Can Capacity Green

$1,150.68 -

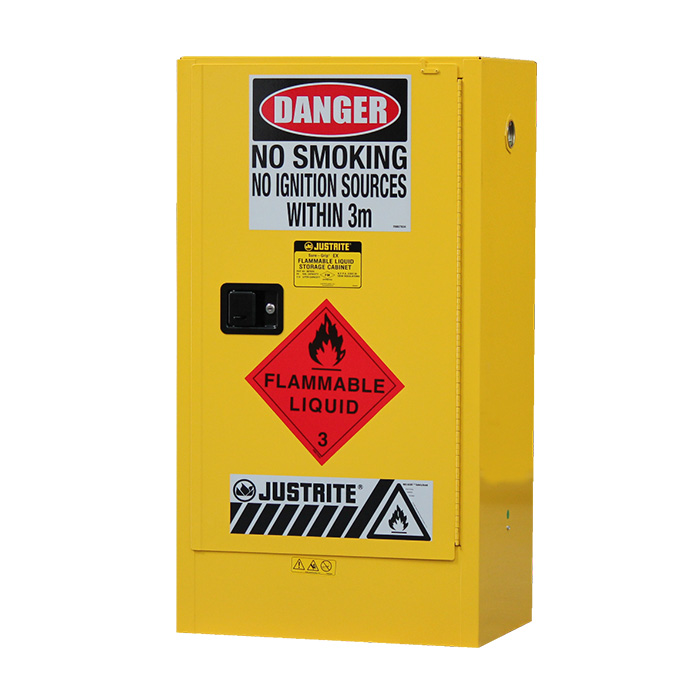

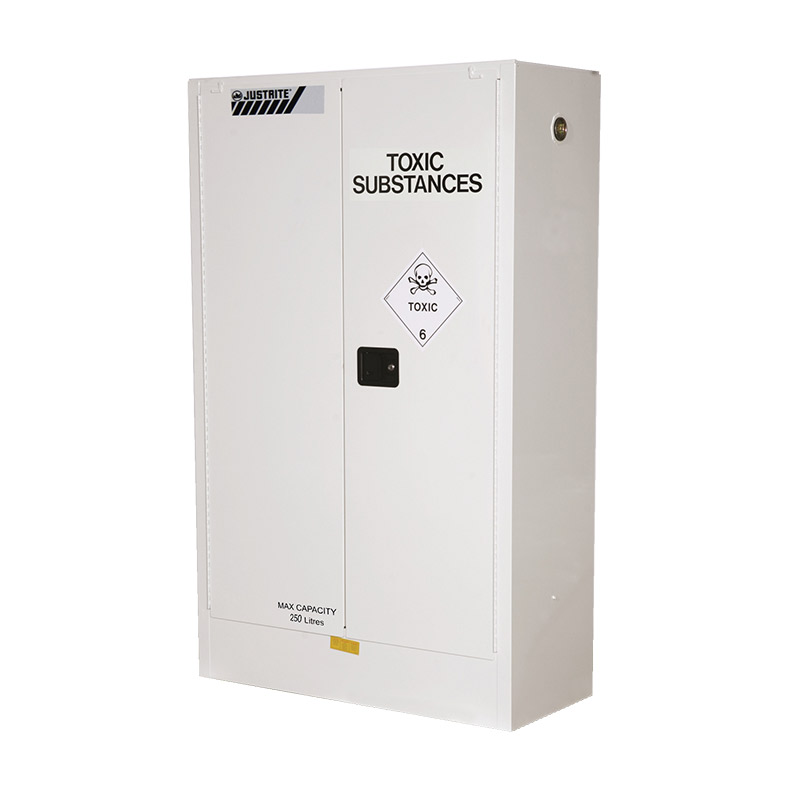

Sale

A24958

Toxic Substance Storage Cabinet 250L

$4,766.97

$3,032.70 -

Sale

A18065

Aluminium Cylinder Lockers, 5-10 Cylinder Vertical Locker with Danger Sign

$3,250.56

$2,317.70 -

A18204

Ezi-Action Drum Pumps - Large 200L

$317.57 -

Sale

A13468

Pesticide Storage Cabinet 250L

$4,981.20

$3,147.10 -

Sale

A41844

Aluminium Cylinder Lockers, 10-20 Cylinder Storage with Oxygen & Gases Sign

$5,485.30

$3,902.80 -

A37891

Tilting Drum Stand

$710.27 -

52948

Wide Mouth Vented Bottle Generic 500ml White 5PK

$217.05 -

Sale

A47073

Oxidising Agent Storage Cabinet 250L

$4,196.40

$3,130.60 -

A18404

Shelving only for 160 & 250L Flammable Liquid Storage Cabinets

$223.68 -

A22571

Syphon Barrel Pump, 1065mm hose length

$150.05 -

A45264

Pre Printed GHS Pictogram Labels- 50mm (1000PK) - Exclamation Mark

$477.04 -

A21286

Pourmaxx Jugs & Buckets - 5 Litre Jug

$39.37 -

A7760

Water Jerry Can, 22L - Green

$103.43 -

A45177

Pre Printed GHS Pictogram Labels- 20mm (100PK)- Flame

$61.73 -

A7761

Metal Jerry Cans Holder

$148.82 -

A23287

SDS Document Storage Boxes Labels Pack

$24.41 -

A45250

Pre Printed GHS Pictogram Labels- 100mm (250PK) - Skull & Crossbones

$406.30 -

A38655

Cabinet Shelf Dividers

$214.85 -

A39655

Fuel Container ID Tags

$4.83 -

A45161

GHS Exploding Bomb Pictogram Labels, 20mm (W)x 20mm (H), Pack of 100 Labels

$61.73 -

Sale

A47867

Organic Peroxide Storage Cabinet Class 5.2 80L Yellow

$3,639.22

$2,615.80 -

Sale

A48126

Corrosive Storage Cabinet Value 30L

$1,571.42

$1,016.40 -

Sale

A48127

Corrosive Storage Cabinet Value 60L

$1,796.26

$1,140.70 -

A48128

Corrosive Storage Cabinet Value 160L

$2,619.44 -

Sale

A48129

Corrosive Storage Cabinet Value 250L

$3,100.34

$2,004.20 -

Sale

A48130

Flammable Liquid Cabinet Value Range 60L Yellow

$1,500.00

$1,157.20 -

Sale

A50138

Underbench Flammable Liquid Storage Cabinet - Value Range 100L Yellow

$1,815.00

$1,336.50 -

A50225

Gas Cylinder Storage Cabinet Single Side Access Small Blue

$1,587.81 -

A50226

Gas Cylinder Storage Cabinet Single Side Access Medium Blue

$1,691.29 -

A50227

Gas Cylinder Storage Cabinet Single Side Access Large Blue

$2,199.22 -

A50228

Gas Cylinder Storage Cabinet Single Side Access Extra Large Blue

$4,091.18